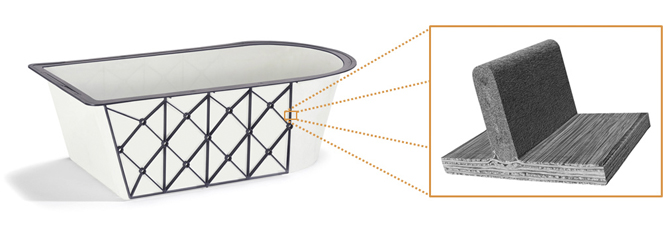

Fiber reinforced composites present a great potential for lightweight construction by stiff and high-strength components. Especially the increasing demands on the mobility sector in terms of lightweight construction and the electrification of it widen the range of applications for line production compatible thermoplastic fiber reinforced composites. Versatile materials with a polymer matrix of PP, PA, PPS or PEEK and a reinforcement with glass, carbon or aramid fibers can be produced. In combination with added functionality via injection molding or sandwich structures with foamed core, tailored components for highly diverse purposes and even structural elements can be designed.

Service Portfolio:

- Material, process and component development for continuous and long fiber reinforced thermoplastic composites

- Processing combining Compression Moulding, Injection Moulding, Foaming, Foam Injection Moulding, Injection Compression Moulding and LFT-Processing

- Component and tool design for combined manufacturing processes (pressing/injection molding)

- Mold validations (combinations of pressing/injection molding)

- Automatized manufacturing cell in an industrial scale including a 2500 t injection press

- Material analysis and component testing for composites