Mouldingmachines:

Energy Foamer 5.0

- Manufacturer: Kurtz GmbH

- Max. mold dimensions: 1200 mm x 1400 mm

- Max. opening stroke: 1500 mm

- 2 pressure filling units: – 90 l each

- Special features:

- Complete online data documentation of all energy consumption

- Mechanical ejector system

- Vacuum

- Crack-steaming

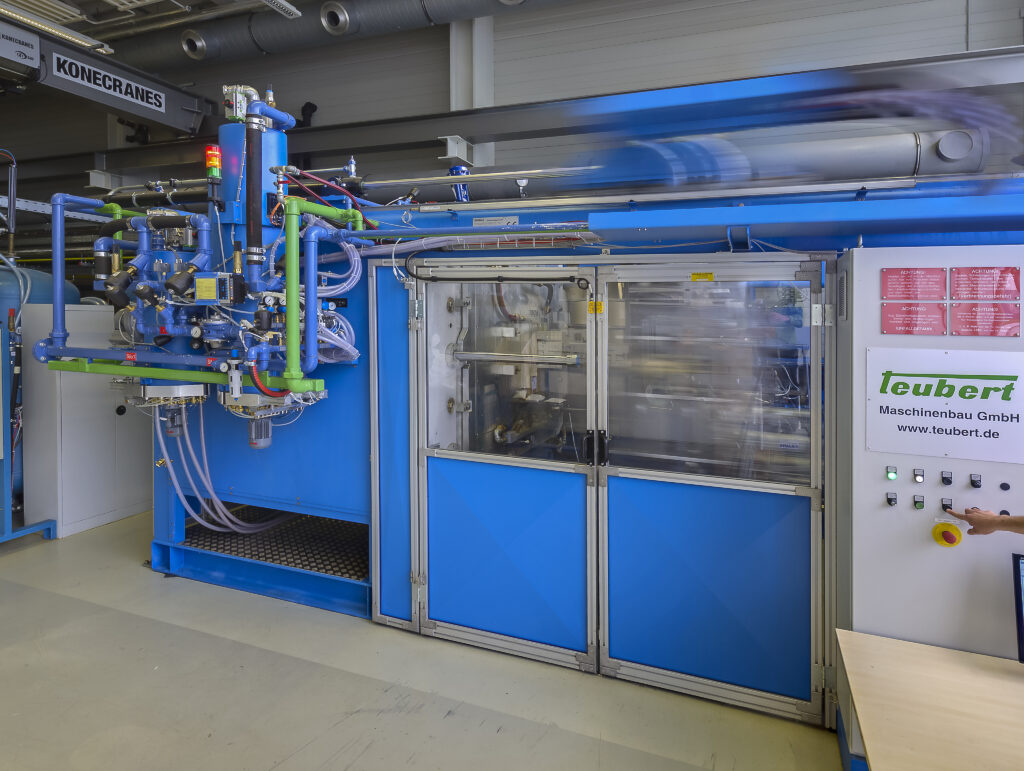

TVZ162/100PP

- Manufacturer: Teubert Maschinenbau GmbH

- Max. mold dimensions: 1620 X 1000 mm (mono block technique)

- Max. opening stroke: 2000 mm

- 2 Eco-pulse pressure filling unit with 75 l and 150 l (applicable for dual-density products)

- Special features:

- Positioning accuracy: +/-0,05 mm

- High pressure steam: up to 25 bar

- Complete online data documentation of all energy consumption

- 4x hydraulic core-pullers

- 8 x pneumatic core-pullers

- Mechanical ejector system (injector-sided)

- Process and support vacuum (separately controllable)

- Parameter documentation and logging function via barcode-system

Transtec72/52PP

- Manufacturer: Teubert Maschinenbau GmbH

- Max. mold dimensions: 600 mm x 600 mm (mono block technique) )

- Eco-pulse pressure filling unit with 30 l)

- Special features: :

- Shuttle technique

- Pneumatic drive control

- Complete online-data logging of all consumed media

- Mechanical ejector system (shuttle sided)

- Parameter documentation and logging function via barcode-system

Wave Foamer C

- Manufacturer: Kurtz Ersa GmbH

- Steamless molding of particle foams by use of electromagnetic radiation in the radio frequency range (27.14 MHz)

- mold dimensions: 600 x 600 mm²

- Pressure filling unit (90 l up to 6 bar) with dosing unit for the adding of liquid auxiliaries

- Chamber pressure regulation up to 5 bar

- Plate mold 100 mm x 200 mm (thickness from 10 to 40 mm)

- Plate mold 200 mm x 300 mm (thickness 10, 20, 40 mm)

- Special features:

- Dynamic mold heating up to 200 °C

- Integrated logging of power curves, foam pressure and temperature

- Complete online data documentation of all energy consumption

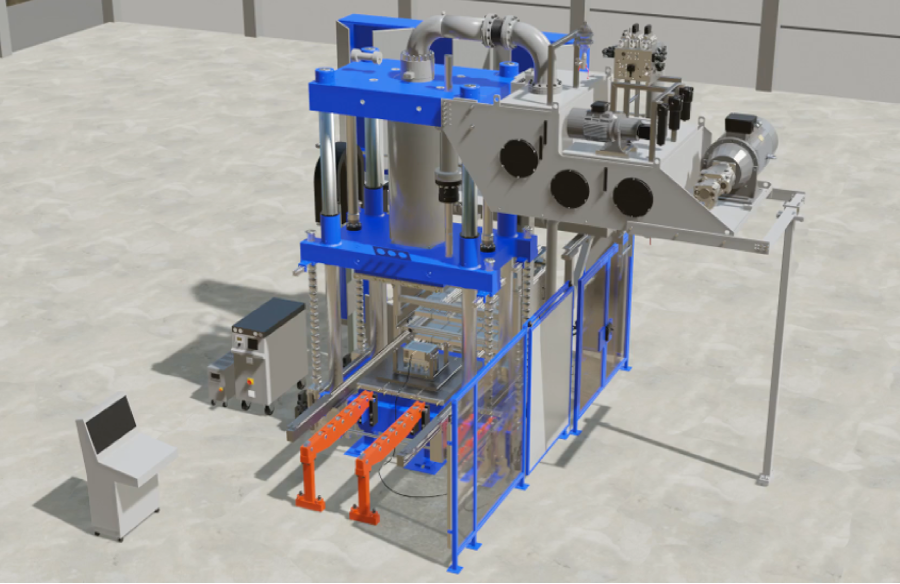

600t high temperature press for steamless bead foam processing

- Manufacturer: Wickert Maschinenbau GmbH

- clamping area: 1250 mm x 1250 mm

- clamping force: 600 t

- Integrated IR preheating station

- Plate mold 200 mm x 300 mm (thickness from 1 mm to 30 mm)

- Special features:

- Complete online data documentation of all energy consumption

- Dynamic mold heating with water. Temperature control unit up to 200 °C

- Dynamic mold heating with oil. Temperature control unit up to 300 °C

- OPC-UA interface

Pre-expander:

IR- pre-expansion oven:

- Manufacturer: Fill Gesellschaft m.b.H.

- Continuous steamless pre-foaming technology

- Pre-foaming temperature up to 250 °C

- Throughput up to 100 kg/h (depending on density)

- Conveyer belt speed: 0.1 – 43 m/min

- Infinitely adjustable emitter height: 50 – 250 mm

- Special features:

- Online energy recording

- 4 modular IR emitter units

- Integrated local extraction system

X-Line 3.0

- Manufacturer: Kurtz GmbH

- Operating pressure: max. 5 bar

- Output: max. 500 kg/h (for EPS @ 80 g/l)

- Max. density fluctuations: +/- 0,5 g/l

- Electronic steam pressure control: +/- 0,01 bar

- Gravimetric dosage

- Suitable for pre- and post foaming of EPS, EPP and other materials

Peripheral:

- Pressure loading equipment: 2 x 1,5 m³

- Steam generation equipment:

- Steam storage: 5 m³

- Steam boiler: 1,1 t steam per hour at 8 bar

- Cooling water storage: 4 m³

- Compressed air storage: 5 m³

- Vacuum cooling system

- Extensive data acquisition by additional sensors

- Cooling water treatment plant

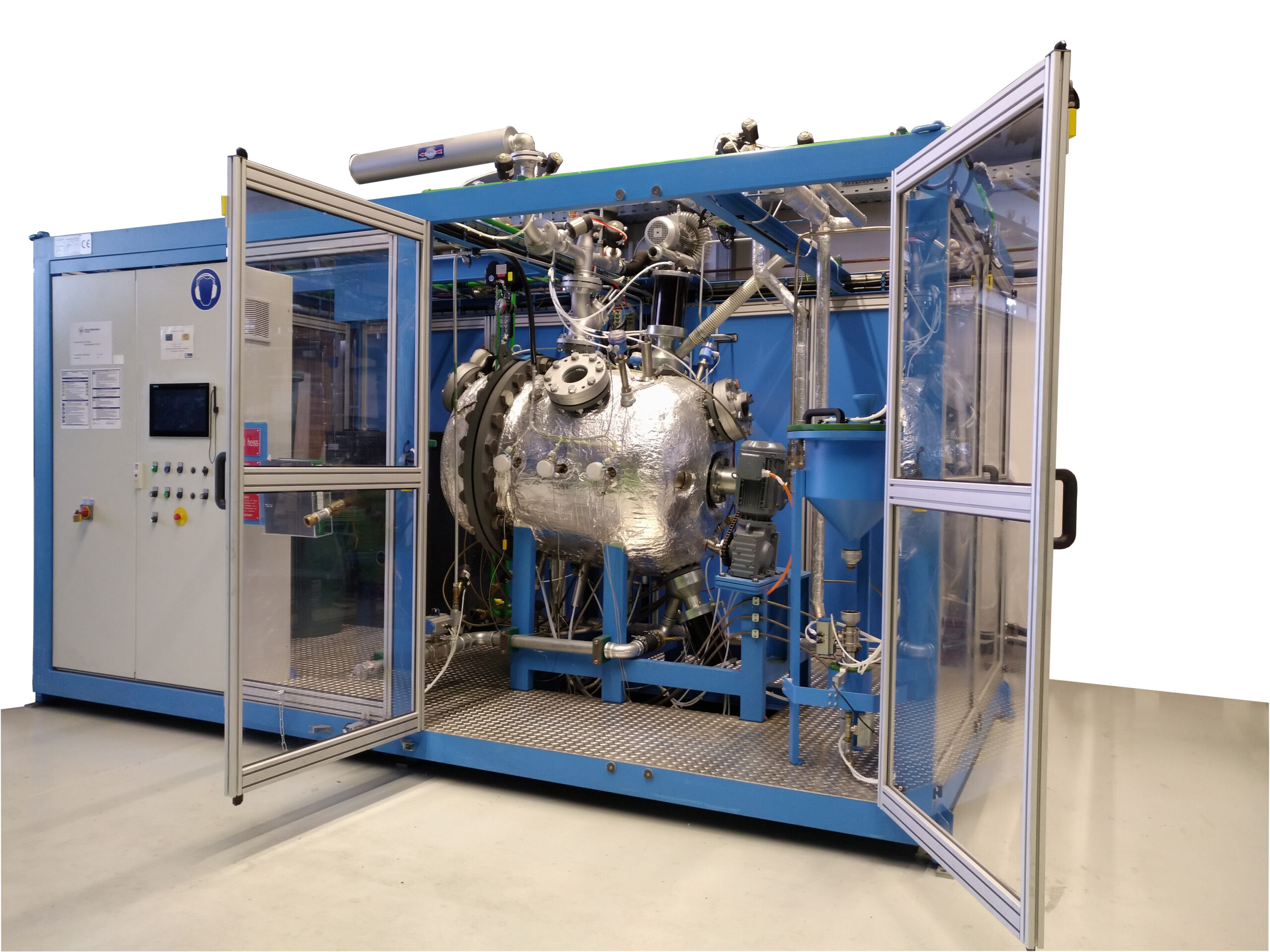

Pressure and temperature conditioning unit (PAT)

- Manufacturer: Teubert Maschinenbau GmbH

- Pressure tank for pressure loading and coating under temperature

- pressure: 16 bar

- temperature: 180 °C

- volume: 350 l

- Special features:

- Gravimetric dosing of solids and liquids under pressure

- Free programmability

- Integrated stirrer